Compressor oil. The principle of operation of screw compressor has been known for 120 years, but the widespread application of these devices began only in recent decades. Initially screw compressors had low efficiency and high cost of rotors.

But scientists kept working to eliminate these shortcomings, and in time their efforts were rewarded with success. Particularly worth mentioning is the work of Swedish Alfa Liskholma.

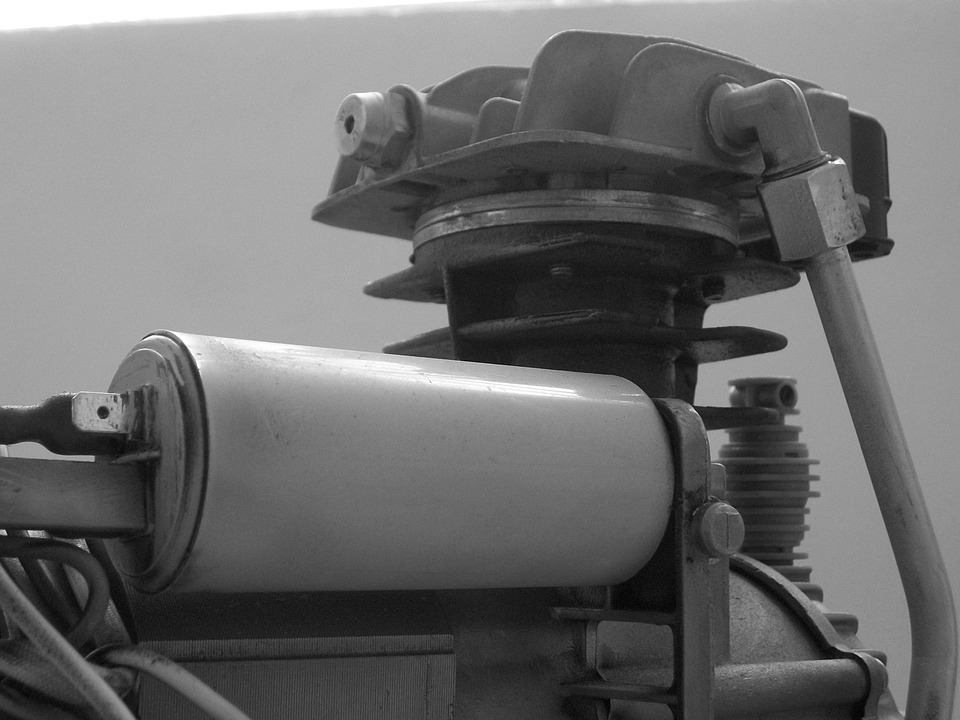

The modern rotary-screw compressor is a positive displacement machine with automatic adjustment of flow and decrease in power consumption at partial load. In contrast to conventional piston-type compressors, rotary-screw compressors have a wider range and lower maintenance costs. They are also characterized by smaller dimensions and lower vibrations.

The industries that use rotary-screw compressors:

- Chemical;

- Petrochemical;

- Gas processing;

- Construction;

- Pharmaceutical;

- Mining, etc.

Compressors are used for cooling, trapping of gases and vapors, as well as compression of natural gas, fuel gas, gas from organic waste, etc.

Compressor oil for rotary-screw compressors

Compressor oil for rotary-screw compressors performs the following functions:

- Cools liquefiable gas;

- Reduce leakage through rotor gaps;

- Lubricates screw rotors.

Rotary-screw compressor oil must meet the following requirements:

- High flash point;

- High water repellent properties;

- Good corrosion resistance;

- Age resistance;

- No foaming.

Other parameters to control are the kinematic viscosity of the oil, it should not be less than 7 cSt, a flash point in an open crucible not less than 180 ° C. The oil should not be mixed with other types of oil. It is recommended to purchase the necessary amount of oil and add oil of the same type only.

Purifying screw compressor oil

Screw compressors must be filled with clean oil. It is the only way to guarantee reliable and long-lasting operation of the equipment.

GlobeCore designs and manufactures oil purification plants for rotary-screw compressor oil which provides:

- Water content below 10 ppm;

- Air content below 0.25% (vacuum degassing);

- Removes solid impurities up to 1 micron;

- Extends lifetime of oil and compressors;

- Increases efficiency of compressor equipment;

- Reduces downtime of compressor equipment