Bitumen Emulsion Storage Tank SBE-30

APPLICATION

Bitumen emulsion storage vessel SBE -30 is designed for operation at asphalt production and repair facilities, road construction, water-proofing and soft roofing facilities, for collection and storage of bitumen based binding liquids, such as water-bitumen emulsions, polymer modified bitumen, thinned bitumen etc.

The unit is designed for operation in ambient temperatures from + 5°С to +40°С.

Technical parameters

|

Parameter |

Value |

|

| 1. Minimum total volume, m³ |

35 |

|

| 2. Minimum usable volume, m³ |

32 |

|

| 3. Agitator rotation speed, RPM |

35 |

|

| 4. Heat exchanger minimum surface area, m2 |

13 |

|

| 5. Heat carrier max volume for heat exchanger, dm3 |

180 |

|

| 6. Nominal power, kW | ||

| – agitator drive |

7,5 |

|

| – total |

22,5 |

|

| 7. Electric power parameters | ||

| – voltage, V |

380 |

|

| – AC frequency, Hz |

50 |

|

| 8. Max dimensions, mm | ||

| – length |

11950 |

|

| – height |

2530 |

|

| – width |

2300 |

|

| 9.Max weight, kg |

12800 |

|

The bitumen collection vessel consists of the following components:

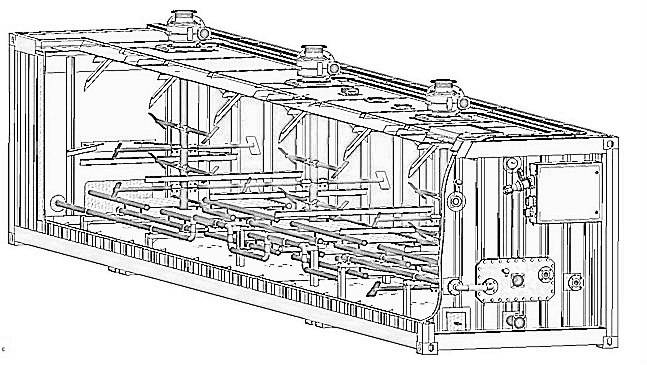

Unit general view: 1 – vessel in frame; 2- service ladder; 3- control cabinet; 4- agitators with drives; 5- heat carrier circulation system (heat exchanger); 6- level sensor; 7- emergency overflow sensor; 8- overflow connector; 9- loading connector; 10- circulation connector; 11- reserve connector; 12-output connector; 13- drain connector; 14- temperature sensors; 15- view hatch

A horizontal insulated vessel pos. 1, made of structural-grade steel, with heat carrier circulation system pos.5. In the lower part of the tank is an output connector pos.12, through which bitumen is discharged to consumers, and a drain connector pos. 13.

Inside the tank there are vane agitators, pos. 4, with drives on the roof of the vessel.

For control of bitumen level in the vessel, a level sensor pos. 6 is installed. To further improve reliability of the vessel, a reserve level sensor (emergency sensor), pos. 7, is installed, which stops the input pump automatically when this level is reached. An overflow connector is installed in the back wall of the vessel, pos. 8.

Control cabinet pos. 3 facilitates control of the unit.

A service ladder is installed on the side of the vessel, pos. 2.

Three input connectors are installed on the roof of the bitumen storage tank: for loading of bitumen (pos. 9), for bitumen circulation (pos. 10) and a reserve connector, which can supplement the main loading connector

Thermistors are installed in the top and bottom parts of the vessel to monitor temperature, pos.14.

The heat carrier circulation system consists of pipelines and insulation jackets. The system can be connected to the process heating system of the facility or a stand alone heater. Industrial oil with operating temperature t = 190 °С is used in the system.

The front of the vessel is equipped with a bi-metallic thermometer for additional temperature control.

For visual control of liquid level in the vessel, a hatch is installed on top of the vessel, which can also be used for servicing of the inside of the vessel.

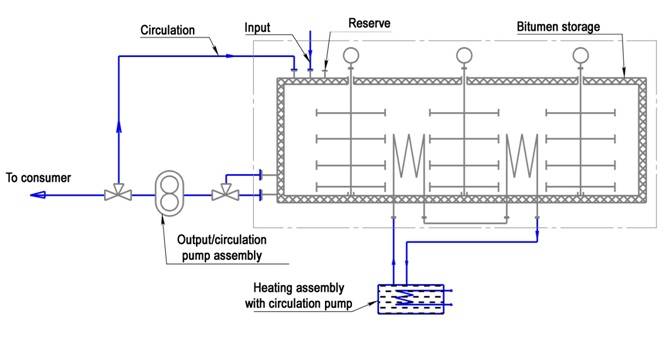

Connection diagram

GlobeCore Bitumen Emulsion Storage Vessel SBE-30

GlobeCore Bitumen Emulsion Storage Vessel SBE-30