Fuller’s Earth Cartriges ZP-260

GlobeCore Fuller’s Earth systems are specially engineered to remove soluble contaminants such as acids, waxes, gums, resins, carbon residues and colloidal particles from transformer oil.

CAPACITY AND DESCRIPTION

The tank with sorbent is a metal cylinder, bottom part of which has a hatch, and upper part is closed by a lid. In the upper part of the tank there is a push button which is used for creating the required sorbent density. Tanks are kept in vertical position by means of clamps.

Cartridge filter consists of cylinder tank, which comprises a filtering element. The filter is equipped with manometer М with measuring range 0 to 12kgf/cm2.Tanks and filter are connected by pipelines. 200 micron brass mesh filter is installed at each section entrance and is designed for oil purification out of mechanical impurities.

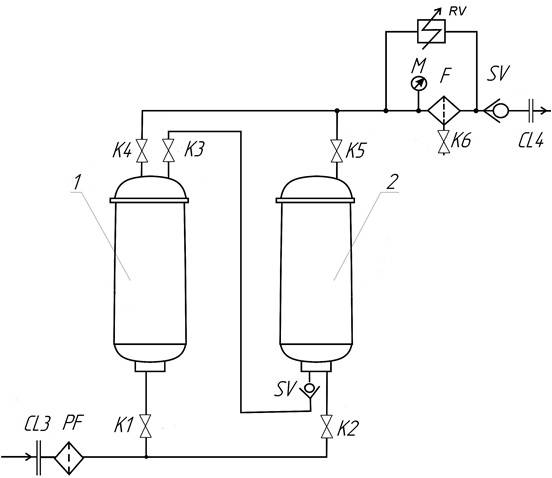

FLOW DIGRAM

Mesh filter FP and cartridge filter F; valves К1…К6; return valve SV; CL3 – nipple of oil input; nipple CL4 of oil output; manometer М; Valves К1 and К2 – input valves to tanks 1 and 2; Valve К3 – valve of tank operation mode; Valves К4 and К5 – tanks output valves, К6 – drainage valve; RV – relief valve.

SPECIFICATIONS

|

Oil Parameter |

Test Method | Before Reclamation | After Reclamation | |

| Appearance | Visual | Cloudy Brown | Clear and transparent | |

| Acid Number, mg KOH/g | IEC 296; ASTM D-664 | 0,63 | 0,01 | |

| Corrosive Sulphur | ISO 5662; ASTM D-1275 | Present | Absent | |

| Tangent delta at 90°C | IEC 247; ASTM D-924 | 4,0 | 0,001 | |

| Oxidation Stability, mg KOH/g | IEC 1125А; IEC 1125B; IP-307 | —- | 0,2 | |

| Surface Tension at 25°C, mN/m

|

ISO 6295; ASTM D-2285 | 22 | 45 | |