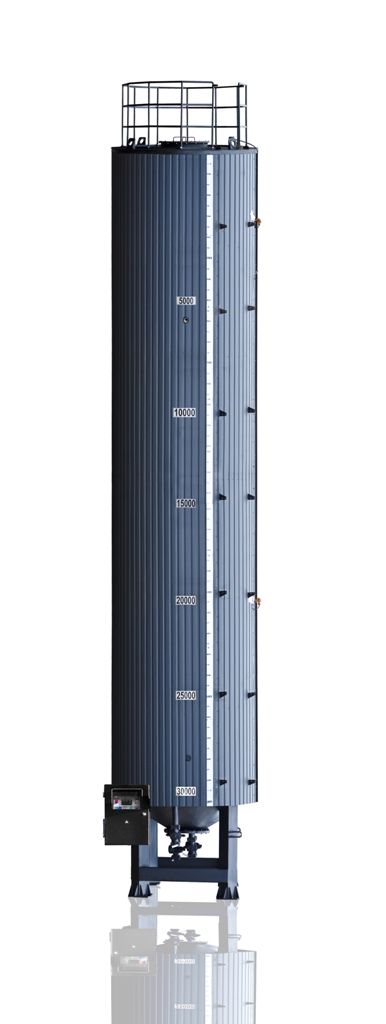

Modified Bitumen Storage Tank SBM-30

Modified Bitumen Storage Tank SBM-30. Polymer modified bitumen is widely used in road and civil construction for production of asphalt mix, laying asphalt, sealing of garbage collection plots, roofing, etc.

This material ensures better resistance to cracking at low temperatures and improved durability of roads, by as much as 10-15 years. However, to achieve these effects strict adherence to correct process parameters and storage conditions is required.

GlobeCore offers the SBM-30 modified bitumen storage tank to business involved in road construction and repairs, waterproofing and soft roof construction. SBM-30 is an insulated tank for storage of polymer-modified bitumen.

SBM-30 components

SBM-30 modified bitumen storage tank consists of:

- vane agitator with drive;

- heat exchanger to maintain the required bitumen temperature;

- emergency overflow line;

- bitumen input/output valves;

- heating medium input/output valves;

- sight hatch and service ladder;

- control cabinet.

The control cabinet facilitates agitator control and storage parameters indications: bitumen temperature and level. An alarm is installed to signal excessive bitumen level.

SBM-30 specifications

|

No |

Parameter |

Value |

| 1 | Total volume, cubic meters |

32 |

| 2 | Usable volume, cubic meters |

30 |

| 3 | Power voltage, V |

380 |

| 4 | Power frequency, Hz |

50 |

| 5 | Power consumption, kW |

30 |

| 6 | Agitator rotation speed, rpm |

400 |

| 7 | Heat exchanger area, sq. meters |

22 |

| 8 | Heating medium volume, liters |

250 |

| 9 | Insulation thickness, mm |

200 |

| 10 | Transportation dimensions, mm: | |

| -length |

12000 |

|

| -width |

2400 |

|

| -height |

2550 |

|

| 11 | Operation dimensions, mm: | |

| -length |

2850 |

|

| -width |

2800 |

|

| -height |

12000 |

|

| 12 | Weight, kg |

8500 |

| 13 | Max loaded weight, kg |

40000 |

| 14 | Calculated load on each support of foundation slab, tons |

10 |

| 15 | Drop of bitumen temperature depending on tank fullness at ambient temperature 5oС, oС in 24 hours |

1-2 |

SBM-30 modified bitumen storage tank advantages:

- reduced heat loss in the bottom due to 200 mm of insulation and the inverted cone shape;

- prevention of rainwater collection at the top;

- bitumen level and temperature control;

- parameter display on the control panel;

- prevention of hot bitumen spills by emergency overflow line;

- optimized design to minimize material cost;

- competitive price.

GlobeCore specialists can also design and manufacture custom bitumen equipment.