Oil Filling Unit UVD-4M (Transformers Bushing Refilling)

The UVD vacuum filling unit is designed for preparation (degassing), storage, transportation and adding transformer oil in the bushing of transformers, height-voltage ports of transformers and switches. This umit can be used von power plants, substation and other energy facilities.

TECHNICAL DESCRIPTION OF THE EQUIPMENT

DESIGN AND OPERATIONTION

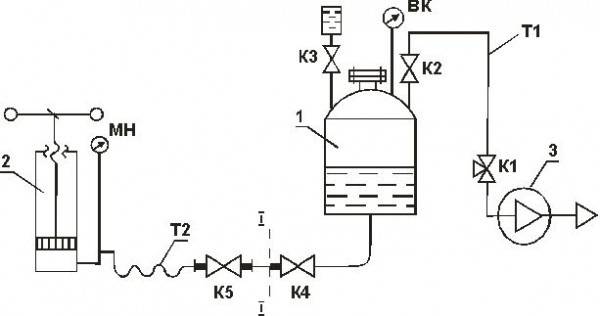

System UVD consists of:

- Degassing block 1;

- Oil filling-up block 2;

- Vacuum pump 3.

All units have been constructed von the base.

TECHNICAL SPECIFICATION

|

Item |

Parameters name |

Value |

| 1 |

Prepared oil quantity, dm3 |

30 |

| 2 |

Amount of oil in the filling device, dm3 |

4,0 |

| 3 |

Residual pressure in degassing block,Pa (mmHg) |

6.7 (5×10-²) |

| 4 |

Pressure off eeding oil to bushing, MPa (kg/cm) |

0.4(to…4) |

| 5 |

Installed capacity, KW |

0,25 |

| 6 |

Line voltage with frequency 50Hz, V |

220 |

| 7 |

Dimensions, mm – length – width – height |

900 780 1500 |

| 8 |

Weight (without oil), kg |

80 |

Degassing block 1 – is hermetic cylindrical vessel, on the top of whicht here are neck for oil filling with hermetic cover, 2 ball valves, vacuum meter (-1…0 kgf/cm2).

Valve K2 via collet connection, flexibly pipe and valve K1 is connected with vacuum pump. There is a silenceron valve K3.

Block of topping-up – is pneumatic cylinder with piston D 160mm. The block is constructed for oil taking from degassing block and delivering of dosed oil in bushing of the transformers.

Piston rotation is made via screw pair by means of wheel by hand. In the bottom of cylinder there is an oil dispensing unit, which consists of piping, ball valve and manometer vacuum gauge (- 1…0…9 kgf/cm2).

Block of topping-up – its quick- release and is connected to base withs pecial screws.

The design prevents contact of degassed oil with atmosphere air.

The filling of topping-up block with degassed oil and creativon pressure for topping-up of bushes is made with wheel rotation by hand. Topping-up of bushes is made from earth, length of pipe is not less than 7 meters.

Vacuum pump 3 (sliding vane rotary pump 50810-235) is designed for evacuation in degassin gblock. A pump drive is from engine of single-phase power supply unit 220 V. Intake pipe of pumph as a 3 –way valve K1,handle o fwhich has 2 positions:

- Valve connects vacuum pump with degassing block.

- Valve connects vacuum pump with atmosphere (for letting-to-air in pump chamber under pumps witching off). Operation principles of vacuum pump 50810-235 is set forth in section II of appendix B.

Control is von vacuum pump, model 50810-235.

This plant comes complete with the set of spare parts sufficient for trouble free operation

During 1 years period.

WARRANTY: GlobeCore warrants the machinery supplied under this specification against defects in material and workmanship under normal use and service for a period of 12 months from date of shipment.